From Cell to Pack

By combining advanced techniques - Electrochemical Impedance Spectroscopy (EIS), Self-Discharge Analysis (SDA), and 3D Ultrasound Inspection - we provide a complete, non-destructive assessment of every cell before it reaches module and pack assembly. Orchestrated through our manufacturing platform - Battery MXP, inspection results become actionable data: traceable, auditable, and seamlessly integrated into your quality management systems.

Cell Inspection without Blind Spots

Honeywell delivers inspection at line rate, with the robustness, service, and integration support required by global pack and module builders. Our legacy in process control and manufacturing execution coupled with cybersecurity means we understand both the science of batteries and the discipline of industrial operations.

Independent Assurance for Pack and Module Builders

By establishing a 100% inbound gate, pack and module builders regain control over quality. No longer dependent solely on supplier certificates, you can validate every cell entering your production line. This reduces the financial and operational risks of escapes, strengthens your credibility with OEMs, and accelerates your ramp-up by avoiding late-stage surprises.

Building for the Long Term

Inspection is not a one-time project. Honeywell supports its customers across the lifecycle, from installation, calibration, upgrades to lifetime support. As the industry evolves and gets increasingly competitive, your inspection backbone evolves with it—protecting your investments today and future-proofing your operations tomorrow.

ROI: The Economics of Certainty

The cost of deploying a robust inbound gate is minimal compared to the consequences of a single defective cell making its way into the field. Honeywell’s customers view inspection not as an added expense, but as a risk-adjusted investment—one that pays for itself many times over in avoided claims, preserved contracts, and brand protection.

100% Cell Inspection: Stop Quality Escapes

Honeywell provides a unified cell inspection suite that goes beyond conventional quality gates. By combining complementary techniques, we give module and pack producers an independent layer of assurance before cells ever enter assembly lines

Electrochemical Impedance Spectroscopy Suite

In under 2 seconds per cell, our EIS systems detect electrochemical irregularities that OCV and DCIR cannot. Most importantly, they provide insights into the quality of the Solid Electrolyte Interphase (SEI) layer, which is critical for long-term cycle life. Subtle deviations in impedance signatures reveal coating non-uniformities, electrolyte distribution issues and early degradation pathways – before they can propagate into packs.

Self-Discharge Analysis (SDA)

As opposed to traditional OCV tests, our unique SDA systems directly measures abnormal leakage currents fast for inline processes, often caused by micro-shorts. The purpose is not to accelerate aging but to detect defective cells much earlier, freeing up storage space, shortening feedback loops and preventing defective cells going downstream.

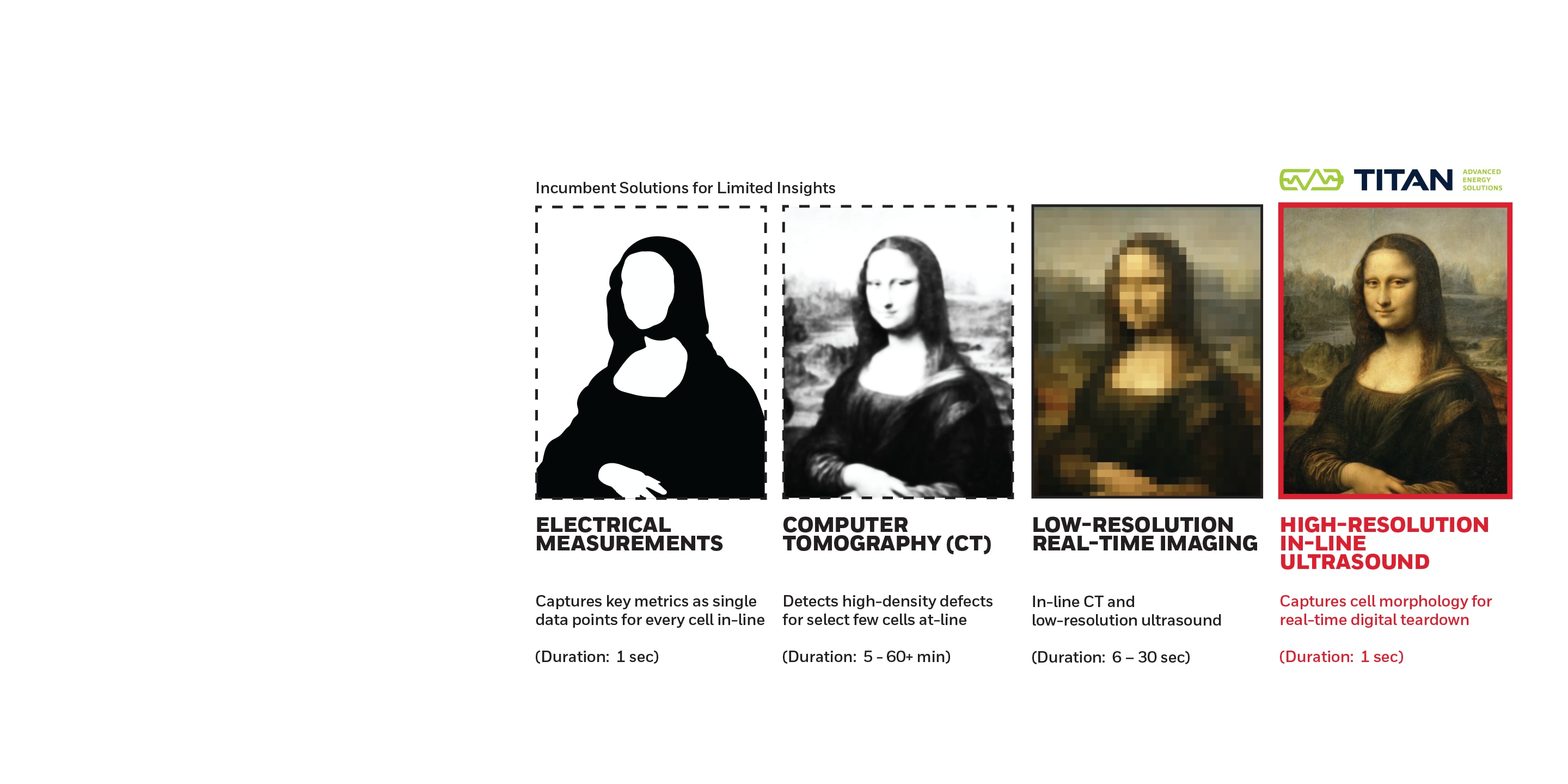

3D Ultrasound Inspection

Ultrasound adds a unique dimension by probing cells in less than one second / cell from multiple perspectives – electrical defects, electrochemical defects and physical defects. In practice, this means detecting defects like misalignments, gas pockets, lithium plating, electrolyte wettability and much more.

Digital Orchestration

These modalities are orchestrated by Battery MXP, Honeywell’s digital manufacturing platform. This consolidates inspection results into a unified data backbone, ensuring every defect is not just detected, but made traceable, auditable and actionable across your quality management system.

Let’s Make Every Cell Count

The performance and safety of your module and pack depends on the quality of every single cell that is integrated into it. One defective cell can compromise an entire pack, cause costly recalls, and erode brand reputation.

Secure your production line and strengthen your position with OEMs. Talk to an Expert!