compressor control

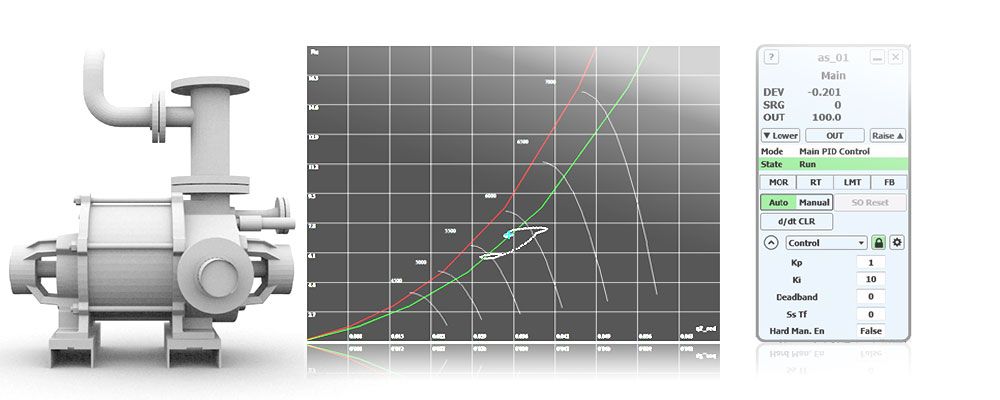

Antisurge Control

Performance, efficiency, and protection - achieve them all with CCC's field proven antisurge control application for centrifugal and axial compressors.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Overview

Centrifugal and axial compressors are susceptible to surge, which can cause catastrophic damage to the turbomachinery train. Antisurge control systems monitor and manage the compressor's operating conditions to prevent surge while optimizing performance. This can lead to better uptime, reduced maintenance costs, higher throughput, and yield.

What Is It

The CCC antisurge control application helps protect turbomachinery trains while maximizing their performance and minimizing energy usage. Its algorithms have been refined and proven through decades of usage across over 10,000 critical production installations to achieve more stable and efficient compressor operations.

How Does It Work?

Antisurge control involves a system of sensors, controllers, and actuators that work together to monitor compressor parameters such as pressure, temperature, and flow rates. The antisurge controller continuously calculates the distance between the compressor’s operating point and its surge limit. The controller modulates a recycle or blow-off valve to prevent the compressor’s operating point from entering a surge while maintaining other process variables within safe and acceptable limits.

The CCC antisurge control application accurately models the surge limit line for all operating conditions of the compressor. It combines both closed and open loop control responses, including the following, to prevent surge without requiring a large control margin while minimizing recycling and unnecessary upsets to the process:

- Antisurge PI Response

- Derivative Response

- Recycle Trip® Response

- Safety On® Response

From a single-stage air compressor to multi-section sidestream refrigeration compressors running in parallel, the CCC standard antisurge control application can be adapted to a wide range of process applications simply through configuration parameters. Some of the key features of the CCC antisurge control application include:

- Fully automated loading, unloading, and emergency shutdown sequencing

- Seamless transition between primary loop and limiting loops (configurable up to 3)

- Invariant coordinate system that handles varying molecular weight and changing process conditions

- Parallel/series machine load-sharing control (with the Performance Control application)

- Recycle balancing between parallel compressors

- Proximity to choke (stonewall) calculation

- Proven antisurge algorithms for sidestream compressors

- Support for variable geometry compressors such as those with guide vanes

- Prevents Surge: Surge can cause significant damage to compressors, leading to costly repairs and downtime. Antisurge control prevents these conditions by keeping the compressor operating within its stable operating envelopes.

- Improves Efficiency: Through accurate characterization of various compressor limits and their fast and sophisticated responses, the CCC antisurge control application minimizes unnecessary recycling and blow-off, which reduces energy consumption.

- Improves Production: Through coordinated response with the CCC Performance Control, it helps maintain more accurate and precise control of the process. This allows for closer operation to process limits and reduced surge control margins, which can lead to higher yield and throughput.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In