Get Super Powered with SmartLine

Dramatically Enhance Maintenance Productivity and Training

By Vincent Higgins

Augmented reality (AR) has the potential to dramatically enhance productivity and training in maintenance. It is, though, just part of a more fundamental shift. Its supporting technologies will have a greater impact.

In some sectors, such as refining and chemicals, maintenance costs constitute the largest operational expense after feedstock. Between 2015 and 2019, oil and gas companies involved in exploration and production spent an average of $80 billion a year on maintenance. Across the process industries, it is a major expense.

In the short term, it is hard to say whether the current challenging times will increase or reduce this. Requirements for employees to physically distance and work from home, along with plummeting demand, have seen many maintenance activities postponed. When sites miss weather windows or scheduled downtime, some tasks will be pushed into the next year or beyond.

Long term, though, two things should be noted. First, essential work must be done and has continued. Safety and regulatory requirements mean plants cannot postpone maintenance indefinitely. Second, the delays to scheduled maintenance carry risks, potentially increasing wear on parts and equipment or letting problems develop. In some cases, at least, plants are storing up problems for the future. Finally, operational expenses are, in most cases, being set against a decline in revenues.

Controlling maintenance costs, therefore, remains a consistent challenge. And a range of technologies will play an increasing role in meeting it.

Changing of the guard

In fact, despite present challenges, many of the current issues for businesses when it comes to maintenance are long standing. Today’s uncertainty has only made them worse. For instance, physical distancing and travel restrictions have in many cases led to reductions in on-site staff, the use of skeleton crews, and increased reliance on remote working and collaboration. But this was an existing trend across a range of industries.

On the one hand, that is driven by the pressure to cut costs and do more with less. Reducing overheads has usually meant efforts to reduce on-site headcounts. It is also informed by another imperative, however: the need to address skills gaps and an aging workforce.

In the energy industry, more than 70 percent of the workforce is over 50 years old. The generation of baby boomers is retiring, taking decades of experience with them. Consultant Accenture Strategy estimated in 2015 that baby boomers accounted for nearly 19 percent of the oil and gas workforce. By 2025 that figure is expected to be just 7%.

In their place come the millennials, already the largest generation in the general workforce. Businesses face a number of related challenges:

· Capturing the knowledge of the retiring workforce and harnessing the remaining expertise of their more experienced workers.

· Passing this knowledge and experience on to millennials, who as a generation prefer experiential learning to traditional classroom-based methods.

· Doing so quickly in the face of increasing staff turnover. Many millennials do not stay in jobs for long. Reducing the time to achieve competency maximizes their period of productive work.

Companies must do all this while promoting the quality of their maintenance, both to foster site safety and to protect against the massive costs of unplanned downtime. Research by the Abnormal Situations Management Consortium shows that individuals directly cause up to 40 percent of abnormal situation losses due to three key contributors: insufficient knowledge, operator oversights, and maintenance work mistakes.

A better reality for teaching

Augmented reality (AR) is starting to become a critical technology in avoiding these losses and meeting the challenges posed by both the current unprecedented times and longer-term trends. The technology has the benefit of being familiar to much of the generation currently entering the workforce. Basic AR technology using smartphone cameras and displays to superimpose graphics and information on the real world has been widely used for games such as Pokémon GO, downloaded over 1 billion times. Combined with smart glasses and wearable computers, AR is also a powerful industrial maintenance technology.

The applications are manifold, and AR has capabilities as both a training and productivity tool. For training, AR functions as a less immersive, but potentially more versatile solution than virtual reality (VR). A VR headset places workers in a fully immersive virtual world, recreating a realistic plant environment, for example. AR, though, can still simulate equipment and project its image using the headset, making it suitable for situations where workers need to retain an awareness of their physical environment. Workers could potentially even use it to learn or rehearse tasks while in the field.

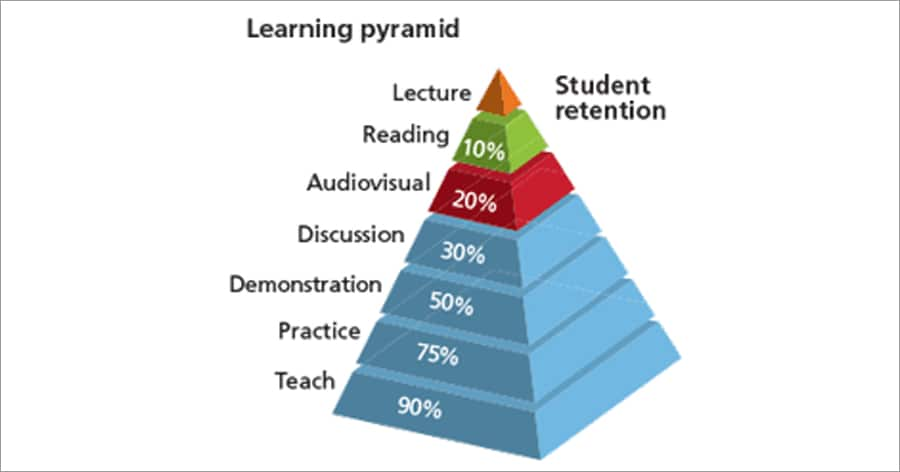

In both cases, the benefits of AR and VR to learning are well demonstrated. The learning pyramid shows that students retain seven or eight times the information from practicing a task compared to reading about it or hearing a lecture. AR and VR offer tools to allow maintenance workers to practice critical, complex, or infrequent jobs in a realistic but safe environment. In practical industrial applications, this has been shown to slash standard times to achieve competency for field workers from six months to two.

The technology is also more flexible than traditional approaches. Rather than requiring trainers to be on site or bringing employees to a central training location, training can be deployed and managed remotely. Experts can view, guide, and assess the activity of trainees using the tool regardless of where they are based. Users can also access training on demand, both for initial training or to refresh or practice new tasks as required. Experienced workers can practice a job in the morning using AR and complete it in the afternoon—arriving in the field fully prepared.

Just as simulation has become essential in the process industries for operator training, AR and VR have the potential to transform the way maintenance workers learn.

Using your head, freeing your hands

VR is primarily a training tool for maintenance; however, AR is also a powerful productivity solution. By combining a heads-up display, wearable computer, and voice recognition, the approach unlocks a wide range of functions and applications:

· Providing information on demand. Giving maintenance workers hands-free access to process information, equipment diagnostics, instructions, and manuals, AR can enhance situational awareness, accelerate troubleshooting, and reduce repair times.

· Video-on-demand can show workers how to complete every day or complex maintenance tasks, providing users with step-by-step guides they can access in the field.

· Front-facing cameras and cellular connectivity can share the field worker’s view with remote experts to offer guidance or instruction, helping prevent errors and accelerate work.

· Tracking, monitoring, and logging maintenance work to monitor asset performance, inform training, and capture accurate maintenance metrics, such as mean time to repair (MTTR) and mean time between failures (MTBF).

With solutions built on top of standard mobile operating systems, businesses can develop bespoke applications, making the tool almost infinitely adaptable.

Providing hands-free access to contextual information, guidance, advice, and tutorials on demand and in the field, AR supports existing maintenance staff. They work more confidently, more correctly, and more quickly. It also enables businesses to send trainees safely into the field sooner, comfortable that they can receive instruction and guidance as required. It will empower a new generation of maintenance staff to learn as they work and work as they learn.

AR is not only a tool to provide access to guidance and expertise; it is also the ideal tool to capture it. Experienced workers using such headsets can capture and catalogue tasks as they complete them on their round, recording the steps taken to complete them successfully.

Although augmented reality is an undeniably powerful technology, it is important to be realistic about its limitations. Crucially, we should note that AR headsets are of little value without a range of supporting technologies. Most obviously, workflow software is the platform on which the AR runs, and it largely decides the effectiveness. It is responsible for the ease and accuracy with which maintenance steps can be captured and shared. And its ability to access and display relevant contextual information will have a significant influence on AR’s value as a tool.

More broadly, all this is also supported by the availability of data and the ability to turn it into actionable intelligence, which relies on two further technologies: the Industrial Internet of things (IIoT) and data analysis. The IIoT and the ubiquity of affordable sensors and transmitters is the foundation of smart maintenance. Cloud-based analysis—able to turn this into intelligence, trends, and reports—can provide the supporting walls.

This information gives AR users in the field essential contextual and diagnostic information that can reduce safety risks, prevent errors, and accelerate repair times. But these technologies have much greater potential.

Transformative technologies

Viewed critically, traditional approaches to maintenance assume either failure or waste. In the first case, run to failure strategies can be effective for easily and cheaply replaceable devices or assets, particularly where redundancy is built in. They are inappropriate for significant or critical equipment, however, and in any case where failure risks costly replacement, safety incidents, or considerable disruption to the process.

For this equipment, businesses employ some form of periodic maintenance, whether according to a standard schedule or adjusted to take a risk-based approach. Maintenance metrics such as MTBF may feed into these, as may MTTR. The first indicates the likely life of the asset, while the latter partly determines the disruption, overall cost, and therefore, risk involved in a failure. In both cases, though, a level of inefficiency is accepted. Maintenance is undertaken and parts replaced in the absence of any faults.

IIoT and analysis software can provide powerful insights for maintenance workers using AR, providing contextual information, improving situation awareness, and directing them to the likely cause of problems quicker. But it can have an even more significant effect in informing maintenance schedules and empowering genuinely condition-based programs of work.

The data from connected devices can detect early signs of impending problems and help determine the work necessary to correct them. It improves how the work is completed by feeding into AR platforms. More importantly, however, it informs when, where, and what maintenance is assigned to eliminate unnecessary work while reducing the risk of equipment failures.

When businesses realize the full potential of the technology, maintenance workers will arrive on site with the right knowledge, tools, and support to get the job done quickly and efficiently. But more importantly, they will be working in the right place and at the right time to have the most significant impact on the operation’s performance.