ccc analytics software

Total Train Performance Advisor

CCC’s TTPA software models the compressor and provides a comparative analysis of the present operation versus original compressor state operation.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Over time, the performance of turbomachinery slowly deteriorates from its original condition. Continuous thermodynamic performance monitoring is essential to achieving operational cost savings without sacrificing process uptime.

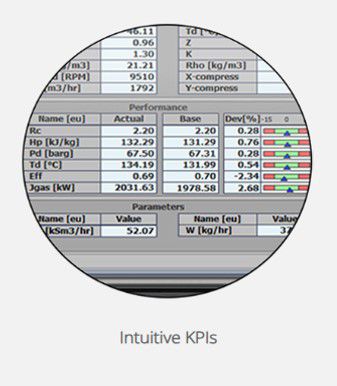

Total Train Performance Advisor (TTPA) quantifies the degradation of a turbomachinery train by comparing its current performance to that of an original, healthy machine. With its accurate performance modeling and easy-to-understand visualizations, TTPA helps the maintenance team make the right operating decisions for the critical turbomachinery trains and validate the results of the online maintenance actions being taken.

What Is It and how does it work?

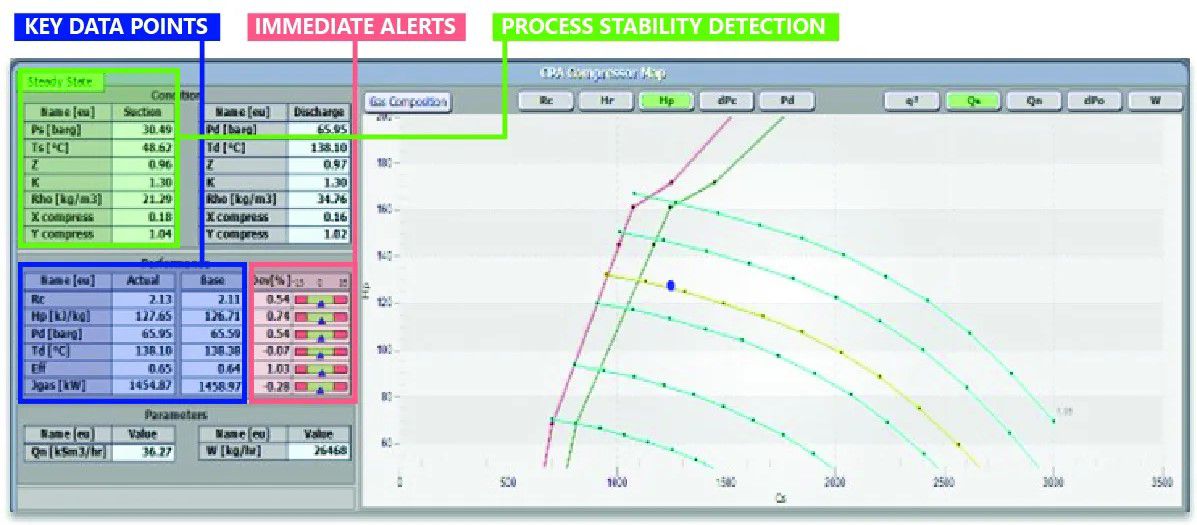

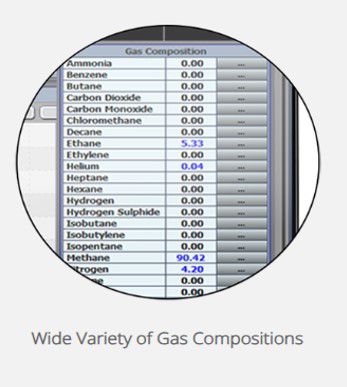

A sophisticated mathematical model is generated for each type of equipment based on original equipment manufacturer (OEM)-supplied performance data. TTPA calculates and displays easy-to-understand health parameters:

- Key Data Points

Those that are critical to understanding the health of a compressor, such as compression ratio and efficiency deviation, are summarized in a simple graphical dashboard. - Immediate Alerts

Percent deviation indicators and configurable alarms immediately notify asset owners when asset performance degradation is detected. - Process Stability Detection

An algorithm helps improve data quality by executing calculations only when the process is at steady-state. - Trending of Performance

Trending of performance parameters over extended period allow to determine if gradual or sudden degradation occurred and correlate the performance to other operational or maintenance events. - Detect Faulty Transmitter

As thermodynamic performance calculations are based on the combination of multiple instrument measurements, TTPA help detects drifting or mis-calibrated transmitters, which may otherwise remain undetected. - Cost Calculations

Quantify the cost of the reduced performance in term of additional power required and related economic impact.

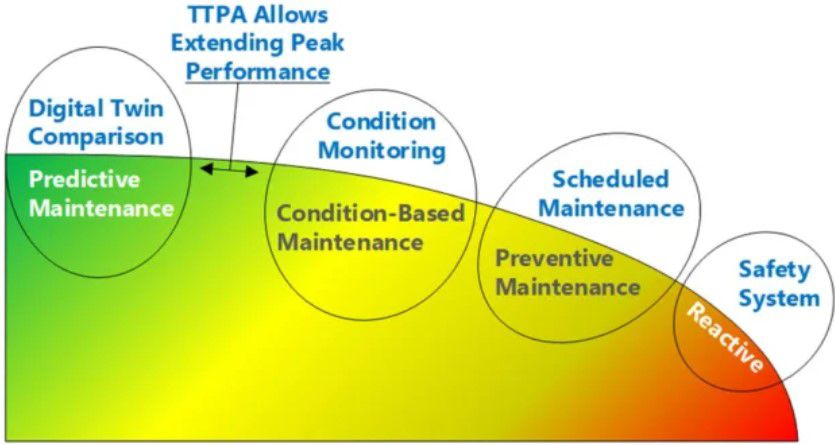

The compressor maintenance model has evolved from reactive (fixing after failure) to preventive (scheduled maintenance), then to condition-based (based on equipment condition), and now to predictive maintenance (using digital twin and data analytics to predict condition). The Total Train Performance Advisor (TTPA) is crucial for modeling dynamic compressor behavior, enabling predictive maintenance. It excels in performance modeling and visualizations, aiding in the detection of issues like fouling and others.

Types of equipment that TTPA can model and analyze:

- Compressor Performance Advisor (CPA) – based on ASME PTC-10 standard

- Steam Turbine Performance Advisor (TPA)

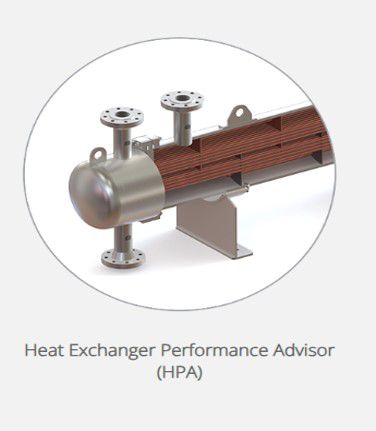

- Heat Exchanger Performance Advisor (HPA)

Who is it for?

TTPA helps the user and plays an important role in calculating economic losses, scheduling maintenance outages and planning the work to be done.

Mechanical and process teams can use it to identify fouling that can cause surge line to occur at higher flow rates, therefore posing a threat to the compressor and reducing compressor operating envelope.

The instrument maintenance team will benefit from identifying instrumentation issues: miscalibration, plugged impulse lines and dry gas seal system excessive leakage.

The reliability and maintenance team will get online performance indicators and KPIs that can be used in the maintenance strategy development.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In