ccc diagnostic software

Transmitter Drift Detector

CCC’s Transmitter Drift Detection feature provides a way to detect and alarm the situation when there's a deviation in a dual redundant transmitter pair when one of them is drifting, but remains within the healthy signal range.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Faulty measurements for signals used by the turbomachinery control systems can result in unit going off-line, a nuisance trip, and consequently, often cause a major process disturbance. The deployment of smart instruments has improved the diagnostic coverage, however, issues such as blocked impulse lines, condensation, and processor failures in the instrument still cause a substantial number of incidents, as evidenced by CCC’s engineers.

What Problems Does It Solve?

Pressure measurements in general and especially differential pressure measurements are susceptible to faulty readings, due to the relatively low level of the signal and its sensitivity to distortions due to issues in the impulse lines.

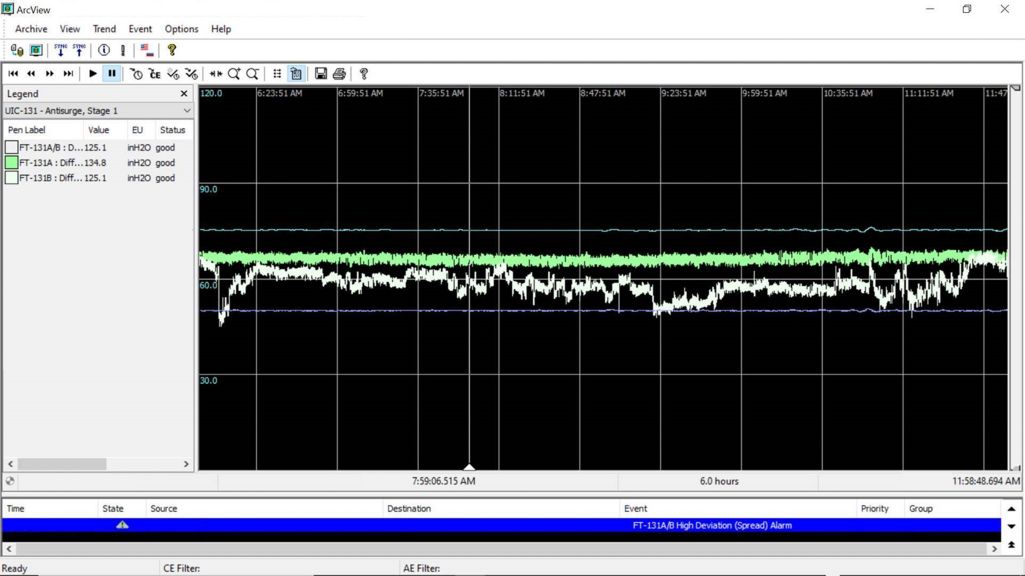

If there’s a deviation between two signals in a dual redundant transmitter pair, the more conservative value is always selected, leading to safer, but often inefficient action from the controller. For example, in the case of dual redundant differential pressure transmitter, if one is showing lower value than the other, the lower reading is usually selected. If that reading falls below the controller setting, it’ll start opening the Antisurge valve.

But what if that transmitter is drifting down because of the aforementioned problem in the impulse line? Main problem is then to identify faulty measurements when the transmitter itself does not provide diagnostics and the signal is electrically “healthy” and reporting “GOOD” status to the system. Still, it may not be correct. This technology allows the user to identify this situation and correctly mark the transmitter as faulty.

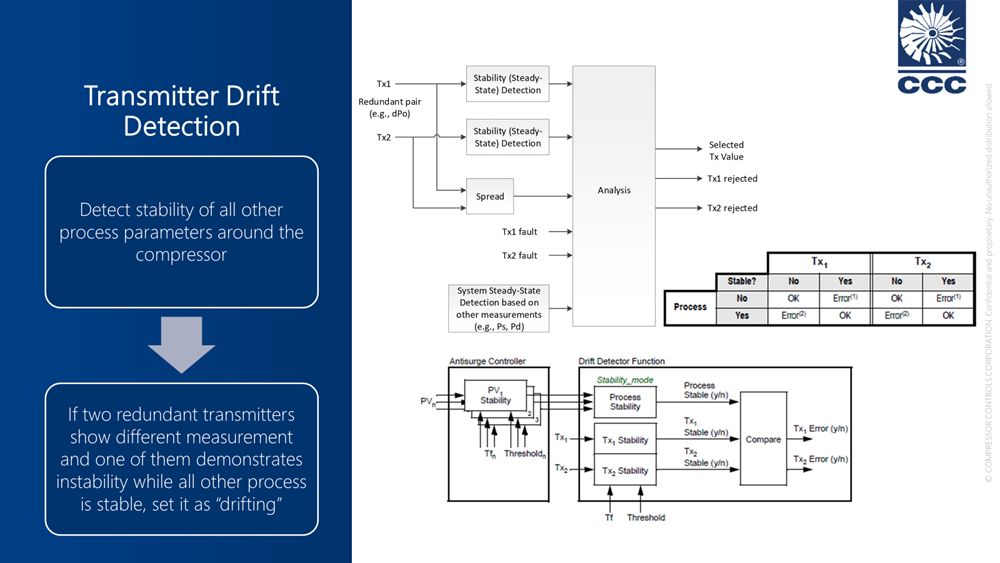

How does it work?

The way to detect failure is to use the correlation with the other measurements coming from the turbo-compressor unit. That is, to use physical characteristics of the machine to reject behavior that does not correlate with the expected machine behavior. For a compressor unit, signals such as flow, suction and discharge pressure and temperature, motor power or current for machines with electric drives, and rotating speed have certain physical relationships between each other. Flow through the compressor can’t change without a corresponding change in pressure ratio, consumed power, or rotating speed.

Dual redundant transmitters are used in CCC projects for the most important part of the project, i.e. Antisurge protection. CCC’s Antisurge application (AS) is necessary and is used as an input to and as the receiver from this algorithm. AS contains a special parameter group called “STABILITY” that is configured to identify the process stability status. The Main controller input processing block receives this information and by comparing the behavior of its own inputs (stable or not) with the rest of the process it can tell if the signal that is changing is showing a real process parameter change or it’s “drifting” without any connection with the real process behavior.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In