driver control

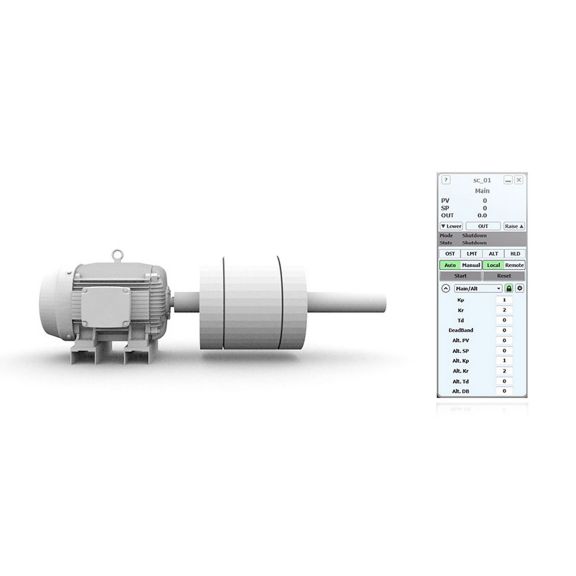

Variable Speed Coupler Control

The CCC variable speed coupler control app modulates torque converter inlet guide vanes (IGVs) to maintain compressor speed. It also adjusts the start-up coupling scoop tube during startups and shutdowns to reduce motor start-up torque.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Overview

In variable-speed centrifugal compressor applications, it can be advantageous to use a fixed-speed electric motor and variable speed coupler (VSC) to drive the compressor, instead of other variable speed drivers such as gas or steam turbines or variable-frequency electric motors. CCC variable speed coupler control enables this loop to be deployed on a single Pro Built control platform along with performance and antisurge loops.

What Is It

CCC variable speed coupler control application modulates the torque converter inlet guide vanes (IGVs) within the variable-speed coupler to maintain the speed of the compressor at the desired set point. During startups and shutdowns, it can also modulate the start-up coupling scoop tube within the coupler to reduce the start-up torque on the electric motor.

How Does It Work?

Variable speed coupler controller was designed to have all the necessary I/O and functionality to interface the Voith Vorecon1. The VSC application’s primary function is to regulate the speed of a compressor to a desired set-point by modulating either the Vorecon’s Torque Converter’s inlet guide vanes (IGV) or the Vorecon’s Hydrodynamic Start-up Coupling’s scoop tube position to ensure that the compressor speed remains within a safe and acceptable range.

Some of the key features of the CCC variable speed coupler control application include:

- Compressor speed may be measured by up to three frequency inputs or three analog inputs

- Two independent Speed Control loops, one for the Torque Converter using the IGVs as its modulating element and one for the Start-up Coupling using the scoop tube as its modulating element

- Bumpless toggling between Remote and Local set points for the Torque Converter Speed Loop

- Overspeed trip function

- Overspeed Avoidance algorithm

- Manual control of both Torque Converter’s IGV and Start-up Coupling’s scoop tube

- Automatic start-up and shut-down sequencing

- Critical Speed Avoidance

- Increases Uptime: Fast and accurate PID controls combined with loop decoupling and overspeed protection help avoid costly downtime even for a sudden load loss.

- Prevents Damage: By automating the sequences, including critical speed avoidance, it can achieve more safe, reliable, and repeatable start-ups and shutdowns.

Please sign in to view part numbers available for purchase based on your account Sign In