ccc diagnostic software

Transmitter Freeze Detector

CCC’s Transmitter Freeze Detection feature provides a way to detect and alarm the situation when transmitter signal is frozen and not showing the actual parameter measurement.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Faulty measurements for signals used by the turbomachinery control systems can result in unit going off-line, a nuisance trip, and consequently, often cause a major process disturbance. The deployment of smart instruments has improved the diagnostic coverage, however, issues such as blocked impulse lines, condensation, and processor failures in the instrument still cause a substantial number of incidents, as evidenced by CCC’s engineers.

What Problems Does It Solve?

Pressure measurements in general and especially differential pressure measurements are susceptible to faulty readings, due to the relatively low level of the signal and its sensitivity to distortions due to issues in the impulse lines. Multiple cases were reported where the signal from the transmitter was not being updated, the value just “froze”.

How does it work?

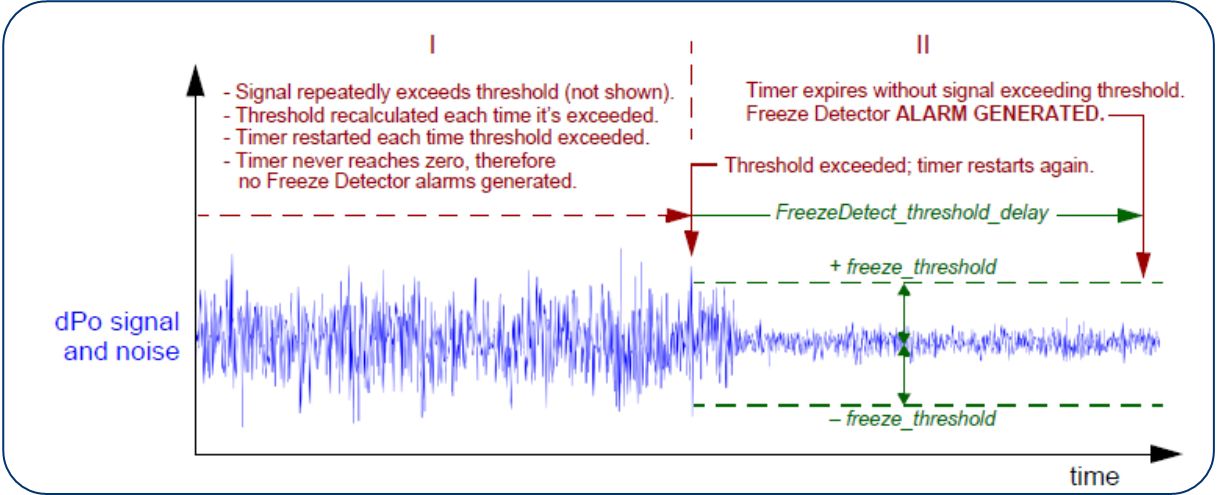

Freeze detector calculates the amplitude of the variations in the signal content. If this variation falls below the normally expected values, the system generates an alarm. The initial values are set during commissioning and can be later tweaked by the engineering personnel.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In