driver control

Power Recovery Train Control

CCC’s Power Recovery Train optimizes energy capture from exhaust gases in industrial processes. It ensures efficient energy recovery, reducing operational costs and boosting overall plant efficiency, while maintaining reliable and safe operation.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Overview

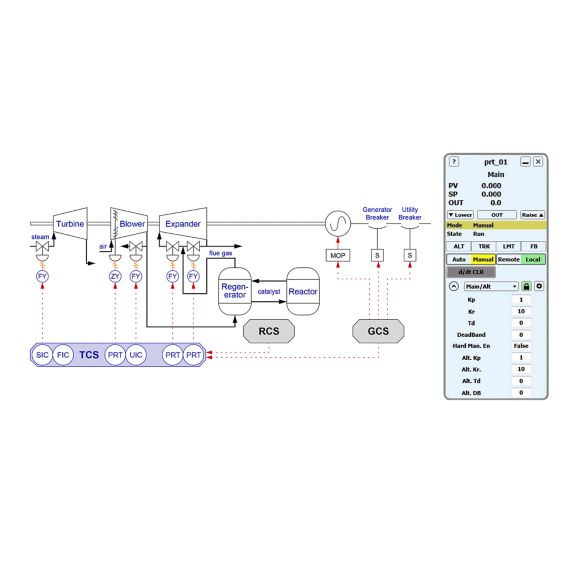

Power recovery trains are commonly employed in fluidized-bed catalytic units (FCCU). They include on the same shaft a hot-gas expander, an air blower, a motor/generator and sometimes a steam turbine or auxiliary motor. The air blower and expander are connected to the regenerator of the FCCU and maintain a required air flow through the unit. The motor/generator may provide power during startup and once there is sufficient flue gas in the expander generates power to the grid. Multiple control applications interact to provide stable control and sequencing for these complex machines.

What Is It

CCC’s control applications are designed to provide coordinated control of all turbomachinery connected on same shaft of the power recovery train.

The power recovery train control application (PRT) regulates the inlet guide vanes and bypass valve for the hot gas expander to maintain proper flow and pressure for the catalyst regenerator. The control application is designed to manage all sequencing and transitions between operating modes, provide multi-variable control and open-loop response to disturbances.

How Does It Work?

CCC’s PRT control application regulates the expander inlet guide vanes and Joule-Thompson valve to provide accurate control of the main process control variable and seamless transition between different operating modes. They are configured to perform automatic sequencing during startup and normal stop and fast open-loop responses in case of emergency shutdown of the expander or braker trip, to minimize process disturbance.

For machines in series/parallel layout, CCC’s proven load-sharing and load-balancing algorithm allows to maximize efficiency and capacity and turndown capabilities.

Some of the key features of the CCC power recovery train control application include:

- Generator power control through expander inlet guide vane opening

- Limiting of regenerator pressure through expander bypass valve opening

- Load-sharing and load-balancing for parallel trains

- Fallback control response to minimize effects of breaker trips

- Forced motoring control to prevent frequent switching between motoring and generation when operating at nearly equal recovered and required power

- Fallback control in case of multiple input signal failures

- Sequencing for the overall power recovery train

- Multivariable Control: power recovery train applications allow stable control of regenerator flow and pressure, while simultaneously maximizing recovered power at the generator

- Simplified Operability: coordinated automatic sequencing of the machine allows operator to more easily startup and stop the train and switch between multiple operation modes

- Parallel Control: load-sharing and load-balancing allow operators to more simply manage turndown capacity and more efficiently balance parallel trains

Please sign in to view part numbers available for purchase based on your account Sign In