ccc diagnostic software

Virtual Redundant Transmitter

CCC's Virtual Redundant Transmitter adds redundancy to the transmitters that don't have a real physical secondary device. Secondary input can come from another device or from the model, depending on the process configuration.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

This function has been designed for Prodigy users who use simplex, i.e. non-redundant, transmitters for turbomachinery control and wish to benefit from enhanced fault tolerant operations.

What problems does it solve?

In case the simplex transmitter which feeds the Antisurge or Performance controllers calculations fails, controller reverts to a Fallback mode which is designed to keep the unit safe and online but has to make safe assumptions in the absence of the real measurement that has failed. Therefore, it is sometimes associated with inefficient operation. This new VRT function allows the system to continue operating safely without triggering the Fallback strategy as long as it is safe and reasonable. It verifies the correlation and validity of the secondary signal automatically and will not allow switchover if the secondary signal does not represent the primary one well enough.

What quantified benefits does it provide?

Adding a real secondary transmitter is very costly and can vary from $3 000 just for additional hardware during a greenfield project up to $50 000 for additional hardware, design docs update, and installation works in case of a brownfield upgrade. This solution allows to use other measurements in the system that are naturally redundant to the primary one. It provides a backup to the real transmitter and delays triggering the Fallback mode that gives Operations time to fix the transmitter and avoid potential inefficiencies associated with Fallback mode.

What are the typical applications where it can be used?

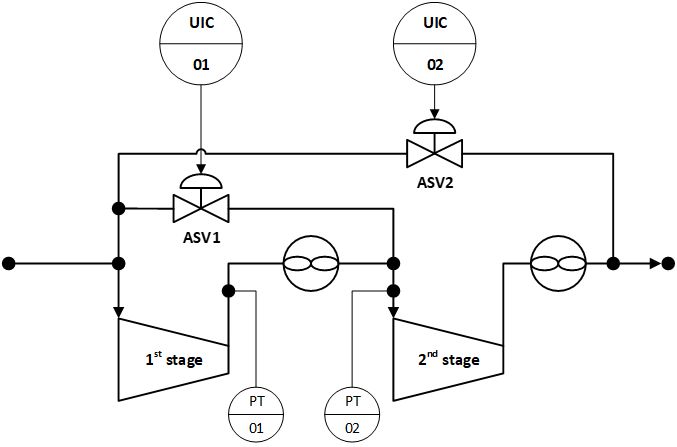

Example 1: in a two-stage compressor, discharge pressure of the 1st stage and suction pressure of the 2nd stage are often measuring pressure in the same pipe, with a static resistance between them. Therefore, they are naturally redundant and can be used as substitutes for each other. See attached figures for examples.

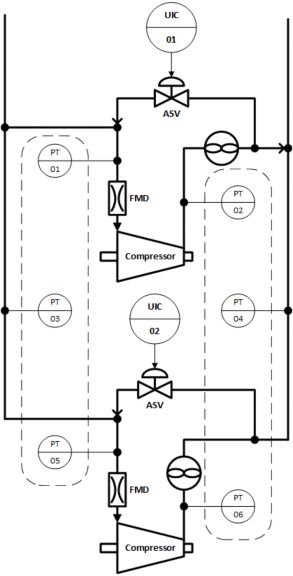

Example 2: when two parallel compressors have a common suction header, they often have separate measurements for the header pressure and in the suction of each of the compressors. All three signals essentially measure pressure in the same pipe and can be used as substitutes for each other. See attached figures for examples.

What specific features are planned to deliver the benefits?

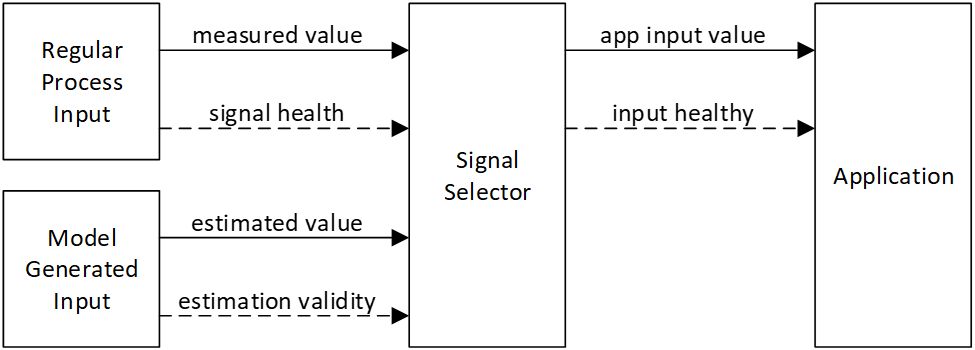

This function block resides between the analog input block and the controller application, i.e. Antisurge or Performance. If the primary AI channel fails and the secondary input is valid, the system switches to the secondary input before the controller triggers Fallback mode. See Figure 1 for that explains the switchover.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In