ccc diagnostic software

Valve Exerciser

CCC’s Valve Exerciser verifies the health of the most important valves surrounding the compressor in less than one minute - without disturbing the process.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

Not all valve issues can be efficiently diagnosed by conventional onboard electronics, which keeps maintenance teams in the dark and puts operations at risk. CCC has made the next step in valve diagnostic technology by combining valve data with process behavior analysis. This holistic approach helps identify failures by verifying that the process behaves as it would when the valve is healthy.

What Is It?

Antisurge valves are key to preventing highly destructive compressor surge events. But even the most high-quality mechanical device lacks 100% reliability, and antisurge valve failures may go undetected because the device is designed to stay closed when the compressor is loaded. The same can happen to the turbine steam valve, which often stays in the same position for long periods of time. This technology verifies the health of antisurge and steam control valves using a partial-stroke test designed to minimize process disturbance.

What Problems Does It Solve?

- In many cases, the antisurge valve fails to open “on demand.” This causes the compressor to surge, which can potentially damage the machine due to increased wear.

- Particularly dangerous are situations in which the valve fails to open on a shutdown, causing repeated surging during the coastdown period.

- There are situations in which the valve stroked normally while the compressor was not operating but failed to respond properly when under a large pressure differential during normal operation.

- Pneumatic actuation system malfunctions such as plugged or leaking impulse lines can also lead to degraded valve performance. In extreme cases, these malfunctions can also trigger a complete failure to respond.

- Excessive tightening of the stem packing can cause jerky valve movement and degraded positioning quality, leading to slow positioning, increased overshoot, or steady-state error.

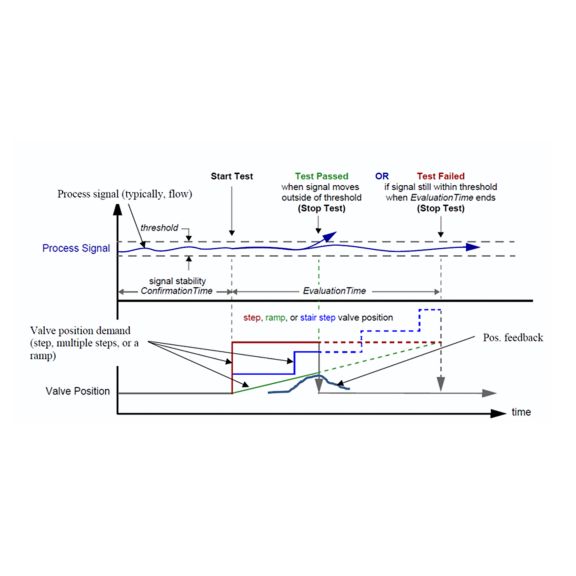

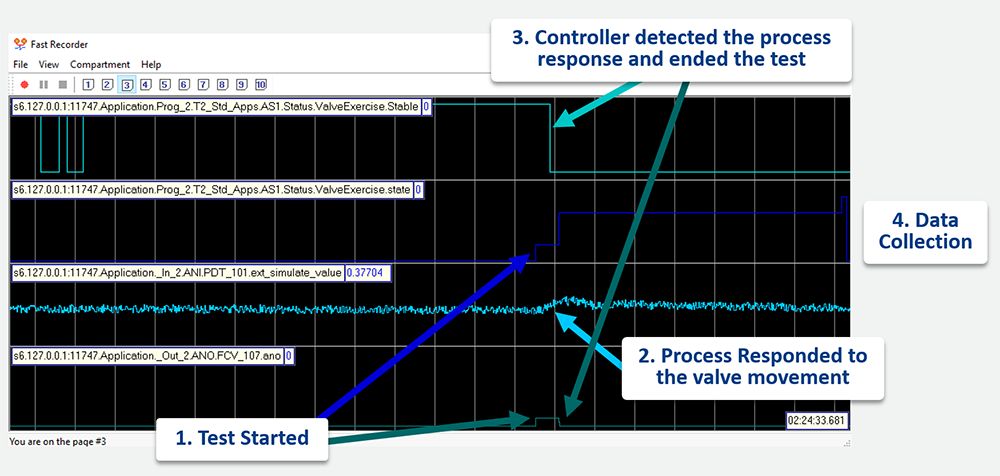

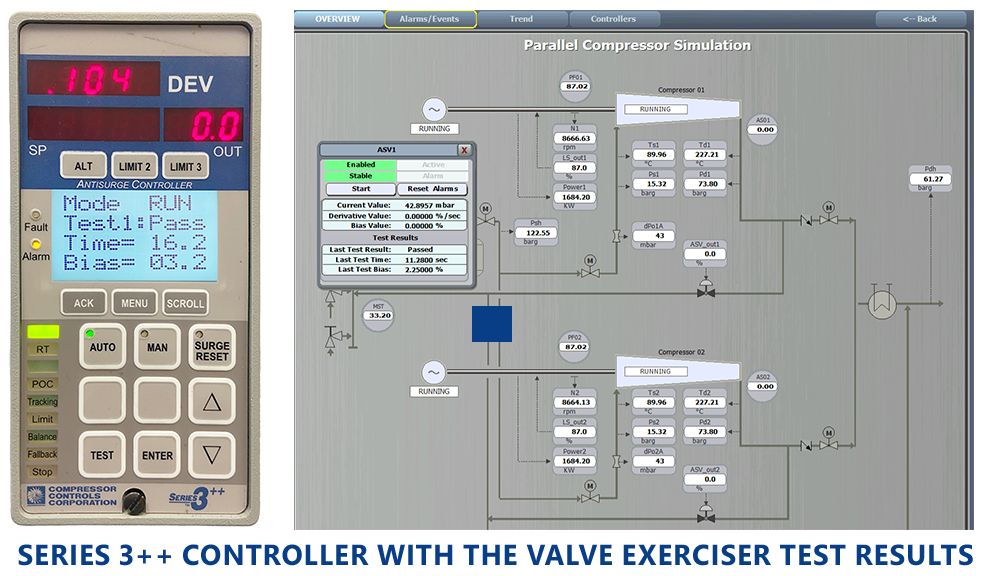

To test the valve performance, Valve Exerciser generates a partial stroke test in the steady-state condition. This test evaluates three configurable signals spanning both process parameters and valve position feedback: Flow (dP) or Speed; Proximity to Surge (DEV); Position Feedback. If the Valve Exerciser detects that the process response is below the baseline or the positioning is not fast enough, it generates an alarm that alerts operators to address the valve condition and plan maintenance. This test is designed to have minimal effect on the process, all while verifying valve health in less than one minute. CCC’s advanced diagnostics functionality helps operators enhance not only their detection capabilities but the overall performance of both antisurge valves and steam turbine main control valves. The functionality for Prodigy/S5P/S5Pro controller and for Series 3++ controller are different. Series 3++ contains the valve health test function. On top of that, the Prodigy/S5P/S5Pro version additionally collects information to assess the valve performance.

- Verify valve health by performing a partial stroke test and record process response.

- Detect valve degradation by calculating the magnitude of the process response and the delay between the beginning of the valve movement and first signs of process reaction. If the process responds weaker or slower over time that can be a sign of valve performance degradation.

- Reduce the risk of increased stiction through periodic movement of the valve during the partial-stroke test. This stiction is typically caused by material accumulation or hydrates formation around the valve plug.

- Avoid process disruption. The partial stroke test makes the smallest possible change in the valve position and quickly returns back to the starting point, so the process reaction will be minimal. The test is only permitted during stable operation when all parameters are under control. The controller performs a standard set of efficient CCC functions that compensate for the mutual influence of the control loops and make the influence of testing on the process negligible.

- Generate a historical analysis of valve performance that enables operators to observe and detect long-developing defects and valve degradation, and predict when the valve will most likely start diverging from the baseline performance and original specifications, which could warrant maintenance intervention.

- Secure comprehensive operator and engineering interfaces for initiating or aborting a stroke test; monitoring test progress; visualizing current test results and results over preceding periods through historical data; configuring stroke test parameters such as stroking type, ramp rate and maximum opening; and automatically initiating periodic tests.

- Implement an automated alarm when the valve performance deviates from baseline by more than the configured tolerance.

- Prodigy, S5P, S5Pro and S3++ controllers

- Antisurge (AS) application for both Series 3++ and Prodigy/S5P/S5Pro

- Steam Turbine Speed Control (SC) applications for Prodigy/S5P/S5Pro

- TrainTools version 15.3 and later

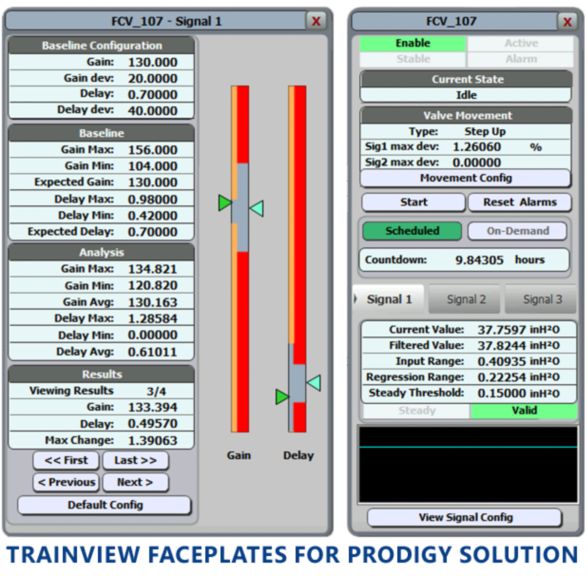

- Main faceplate for both Series 3++ and Prodigy/S5P/S5Pro

- Configuration TrainView Faceplate for Prodigy/S5P/S5Pro

- Full set of configuration parameters accessible from Configurator

- All parameters are historized in the TrainView Historian, if installed

- Main analyzed parameters:

- Compressor Flow (for AS) or Speed (for SC) measurements

- DEV (operating point)

- Auxiliary parameter, if available:

- Valve position feedback through current position feedback or HART

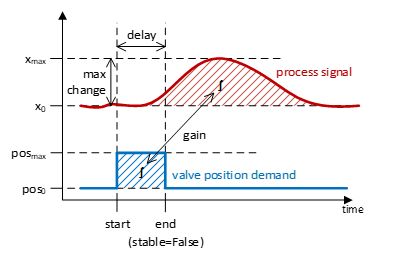

- Main calculated parameters, available only for the Prodigy/S5P/S5Pro version:

- Gain, calculated for each of the three signals. Represents process response normalized against valve opening.

- Delay, calculated for each of the three signals. Represents the time it takes the process to respond to the valve movement.

- Requires preliminary commissioning effort by CCC field engineer to set the baseline and configure a few other tuning parameters.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In