qcs se

Cross Direction Controls

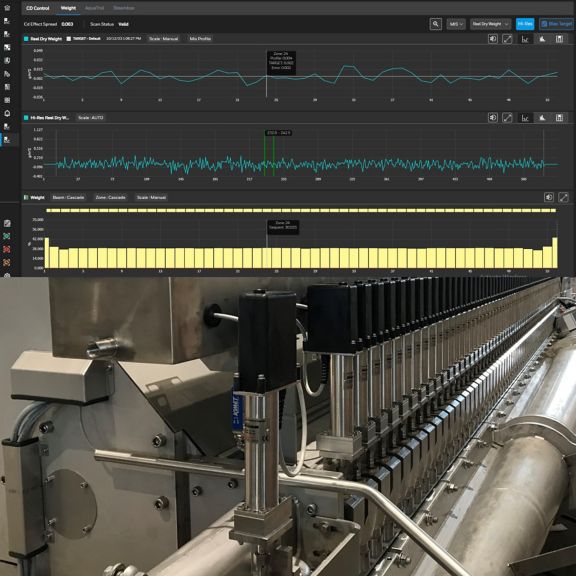

QCS SE Cross Direction (CD) controls ensures product quality and downstream runnability that improves the economics of paper-making and other sheet manufacturing processes through better resource utilization and increased production efficiency.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

QCS SE Cross Direction (CD) control is a multivariable control solution specifically designed for continuous sheet manufacturing processes and used for coordination of multiple CD actuator beams, optimizing multiple sheet properties. It uses a model of each actuator’s effect on each sheet property and takes the physical limitations of the actuator explicitly into account when calculating new optimal actuator setpoints. CD control is a model-predictive controller and after each measurement scan it calculates optimal setpoints to minimize future predicted variation in sheet properties. To ensure all controllable variation is seen by the controller, all calculations are performed using high resolution profile information to avoid loss of data through filtering. Sustainable mapping of CD control is ensured by unique adaptive alignment functionality that continuously monitors control performance to detect any significant changes in actuator alignment. This occurs in the background during normal production operations, with the CD controls in closed loop, and has zero impact on production quality.

QCS SE CD control comes with the award-winning IntelliMap® tool for easy commissioning and maintenance. IntelliMap® automates bump tests to identify the actuators’ responses in all downstream measured profiles and automatically calculates the global process model, as well as optimization parameters based on simple user inputs for maximum overall CD performance. IntelliMap® allows the user to simulate new process model and optimization settings prior to parameter deployment.

Key Features:

- ·Model-Predictive Cross Direction Controls

- ·Adaptive Alignment Functionality

- ·Intellimap® For Ease of Commissioning and Maintenance

What Problems Does it Solve?

Honeywell’s model-predictive CD control solution is designed to maximize each actuator’s contribution for holistic product quality and production efficiency. Tight coordination of all actuator beams increases speed of recovery from process upsets and allows economic targets to be pushed way beyond what is achievable with traditional technology.Advanced optimization features of QCS SE CD control technology enable potential energy savings, target shifts and production increases on paper-making and other sheet manufacturing processes – while adaptive alignment and the easy-to-use IntelliMap® tool provide long-term control performance and reduce maintenance costs which results in improved total cost of ownership.

Brochure

Please sign in to view part numbers available for purchase based on your account Sign In