fixed gauging

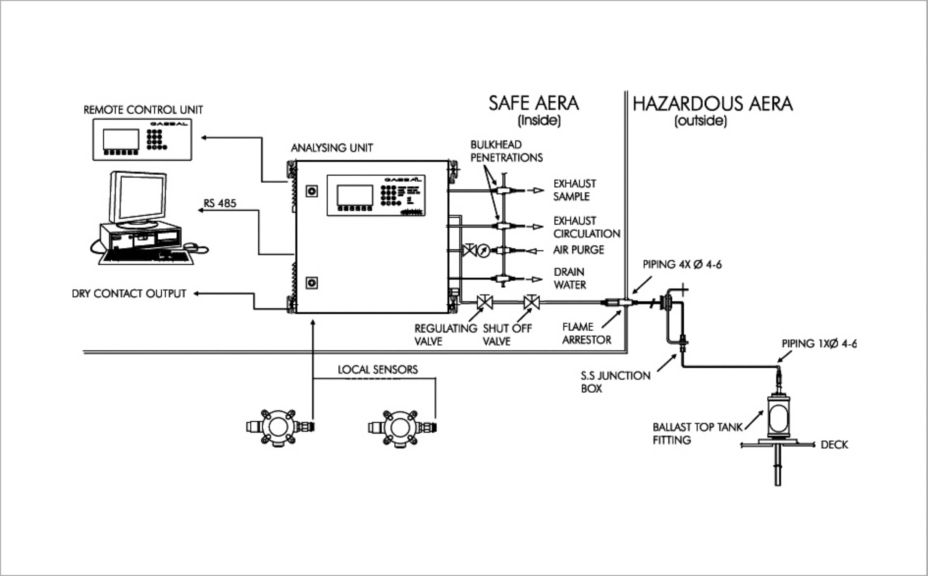

GASBAL™ Gas Detection System

The GASBAL™ is a suction based gas detection system suitable for detecting unwanted gas formation in Ballast Tanks, Dry Void Spaces and Pumo Rooms.

Please sign in to access more documents

Once signed in, you may be able to access additional documents for your account.

The GASBAL™ system is designed to detect and analyze gas concentration in enclosed spaces such as ballast tanks, voids or dry spaces. This gas detection system can be installed on board tankers, OBOs, offshore vessels and rigs and any other ship types requiring empty space gas detection.

Features and Benefits:

- Large capacity: 24 suction channels +6 stand-alone

- Analyzing up to 7 different gases

- Large display unit

- Protection valves on suction pipes, reduce risks of water being pumped into the electronics

- Digital connection with ballast gauging system closes the conduits automatically when water starts pouring in

- Single-source tank gauging and safety

- Possibility to combine sampling method and local gas sensors

- Modbus RTU communication Protocol

- 2 digital RS485 communication ports

- Remote control unit

- Option: Analog transmitter scanning

The GASBAL™ consists of two main units:

- An analyzing unit, including up to seven different gas sensors and up to 24 input channels for sampling and 6 channels for 4-20mA inputs for external sensors,

- A control unit for local and/or remote operation, fitted with an LCD display and a keyboard allowing set up, operation, checking and maintaining the GASBAL™ equipment.

Two digital RS485 ports allow control and communication with any host computers. The GASBAL™ analyzing units and local detectors are delivered with factory calibration, covered by Honeywell Marine’s Certificate. Due to restrictions on Gas transportation, vessel should have relevant calibration gases available onboard (supplied by shipyard or local supplier).

What Problems Does It Solve?

All ships have liquid hydrocarbon tanks (whether engine fuel only or also cargo) with potential leakages. The detection of hydrocarbons is demanded by SOLAS Chapter II – 2 Regulation 5.10.1 and a small leakage in an empty, unmanned space can lead to the formation of highly explosive atmospheres. Gasbal’s simple, powerful system provides regulatory compliance and safety with a low footprint and low cost of ownership – all based on Optima Plus and XCD proprietary gas detectors and manufactured by Honeywell Safety and Product Solutions.

Data Sheet

Filters

Please sign in to view part numbers available for purchase based on your account Sign In